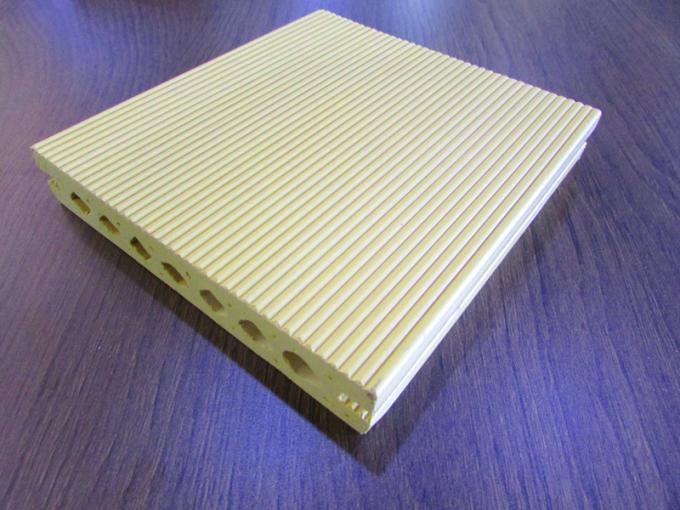

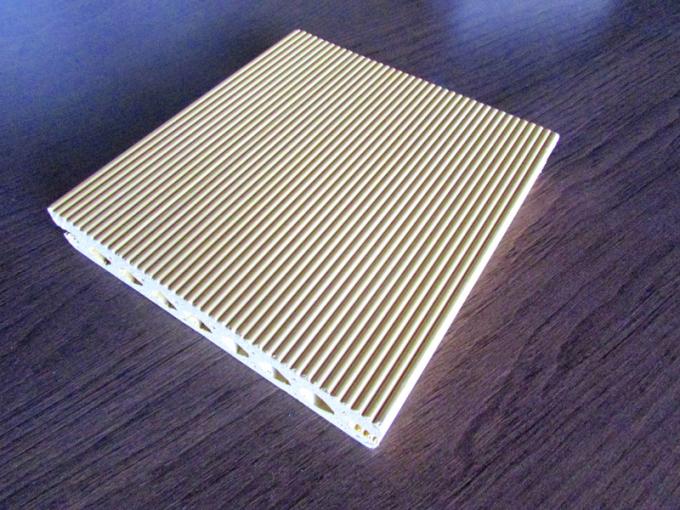

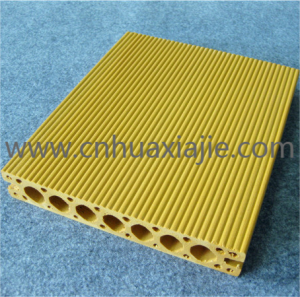

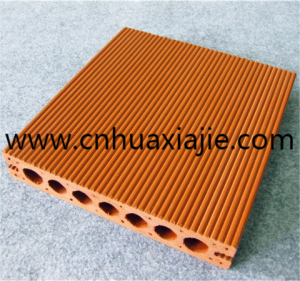

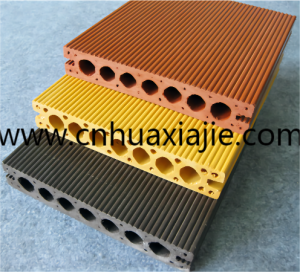

Moistureproof Hollow WPC Composite Decking Plates Outside Environment

| Material: | Wood And Plastic Composite | Name: | Colorful Hollow WPC Composite Decking Plates For Outside Environment |

|---|---|---|---|

| Feature: | Antislip/ Moistureproof / Co-extrusion/ASA/Hollow | Color: | Creamy White, Dark, Yellow Or Customized |

| Application: | Outside Environment | Size: | 140 X 28 Mm |

| Length: | Customized | ||

| High Light: |

Composite Wood Decking, Composite Deck Boards |

||

Moistureproof Hollow WPC Composite Decking Plates Outside Environment

Description:

Characteristic of Composite Decking Plates:

| 1 | Green material,recyclable |

| 2 | Easy to maintain and install |

| 3 | Durable - moistureproof and antislip |

| 4 | Stronger and more Flexible |

| 5 | Standard wood working tools can be used |

| 6 | UV-resist and color stability |

| 7 | Dimension stability against moisture and temperature.suitable from -40 to 60 |

| 8 | Weather resistant, suitable from -40 to 60 |

| 9 | Green ecological, Innovative technology, Lifestyle |

| 10 | Elegant nature wood grain texture and touch, with wood scent |

| 11 | Elegant and detailed shape design |

All the standard embossing is available with this option.

It offers the best combination of price and quality.

Different surface treatment options are available as added features.

The unique embossing patterns enhance the beauty of the boards,

as well as adding to its authenticity.

Beauty/Strong/Dependable.

Specifications:

| Name | Colorful Hollow WPC Composite Decking Plates for Outside Environment |

| Size | 140*25mm or Customized size |

| Length | 4ft or Customized |

| Color | Teak, Beech, Black Walnut, Coffee, Customized color |

| Material component | 60% PVC+30% Wood Powder+10% special additives |

| Surface | Hollow, Smooth, Brushed, Scratched, Grain optional |

| Warranty | 15years |

| Certificate | ISO9001, ISO14001, CE, SGS |

| Lifetime | 25years |

| Package | pallet with PVC soft flim |

| Range of use | Garden, Lawn, Balcony, Corridor, Garage, Pool&SPA Surrounds, Boardwalk,

Playground |

Zhejiang Huaxiajie Macromolecule Building Material Co., Ltd., which was established in 2004, is a special manufacturer of PVC wall and Composite Decking Plates, PVC doors and doorframes, and plastic-wood skirting and flooring. Our products are environment friendly.

With advanced production lines from Germany and Italy, we have a total annual capacity of over 5 million square meters PVC wall and ceiling panels, over 6,000MT plastic-wood products, and over 2,000MT other PVC products.

Test Reprot:

Table 2.Test Results

| Test Method | Characters | Result |

| ASTM G155 | Weathering Resistance | After 2000hours weathering test

Grey scale:3 There was some color changer on the surface. |

Table 2

| Test Method | Characters | Result | ||

| ASTM D 256 | Impact resistance | 59.1 J/m

Break type Complete break |

||

| ASTM D 790 | Flexural strength

(Thickness:3mm,span:48mm) |

MOR::79.8Mpa

MOE:3107Mpa |

||

| ASTM D1037 | Water absorption and

Swelling in thickness (24hours immersion) |

Water absorption:0.16%

Swelling thickness:0.10% |

||

| ASTM D2395 | Specific gravity | 1.17g/cm3 | ||

| ASTM D4060 | Abrasion Resistance

(CS-17,2000cycles) |

Weight Loss:0.12g | ||

| ASTM D696 | Coefficient of linear

thermal expansion (-30℃~30℃) |

5.13*10-5 1/℃ | ||

| ASTM D2394 | Slip Resistance Test | Static Slip Resistance | Dynamic Slip

Resistance |

|

| Dry surface | 0.63 | 0.45 | ||

| Wet Surface | 0.69 | 0.68 | ||

| ASTM D638 | Tensile strength | 37.2MPa | ||

| ASTM

D7032and ASTM D6109 |

Flexural strength:Initial

(Thickness:27mm,span 432mm) |

MOR:33.2Mpa

MOE:2073Mpa |

||

| Flexural strength Temperature

and moisture effects(-29℃ for 7days) |

MOR:35.0Mpa,increase 5.4%

MOE:2209Mpa, increase 6.6% |

|||

| Flexural strength Temperature and

moisture effects(52℃ for 7days) |

MOR:35.2Mpa,increase 6.0%

MOE:2162Mpa, increase 4.3% |

|||

| Flexural strength Temperature

and moisture effects(immersing in water for 7days) |

MOR:33.4Mpa,increase 0.6%

MOE:2103Mpa, increase 1.4% |

|||

| ASTM D7031

and ASTM D6109 |

Flexural strength

(Thickness:27mm,span:432mm) (After freeze-thaw resistance) |

MOR:33.4Mpa,increase 6.0%

MOE:2167Mpa, increase 4.5% |

||

| ASTM D1761 | Fastener withdrawal test | 2387.8N | ||