Cost Price Environment-Friendly printed pvc cladding ceiling panel for Decoration

- Quick Detail:

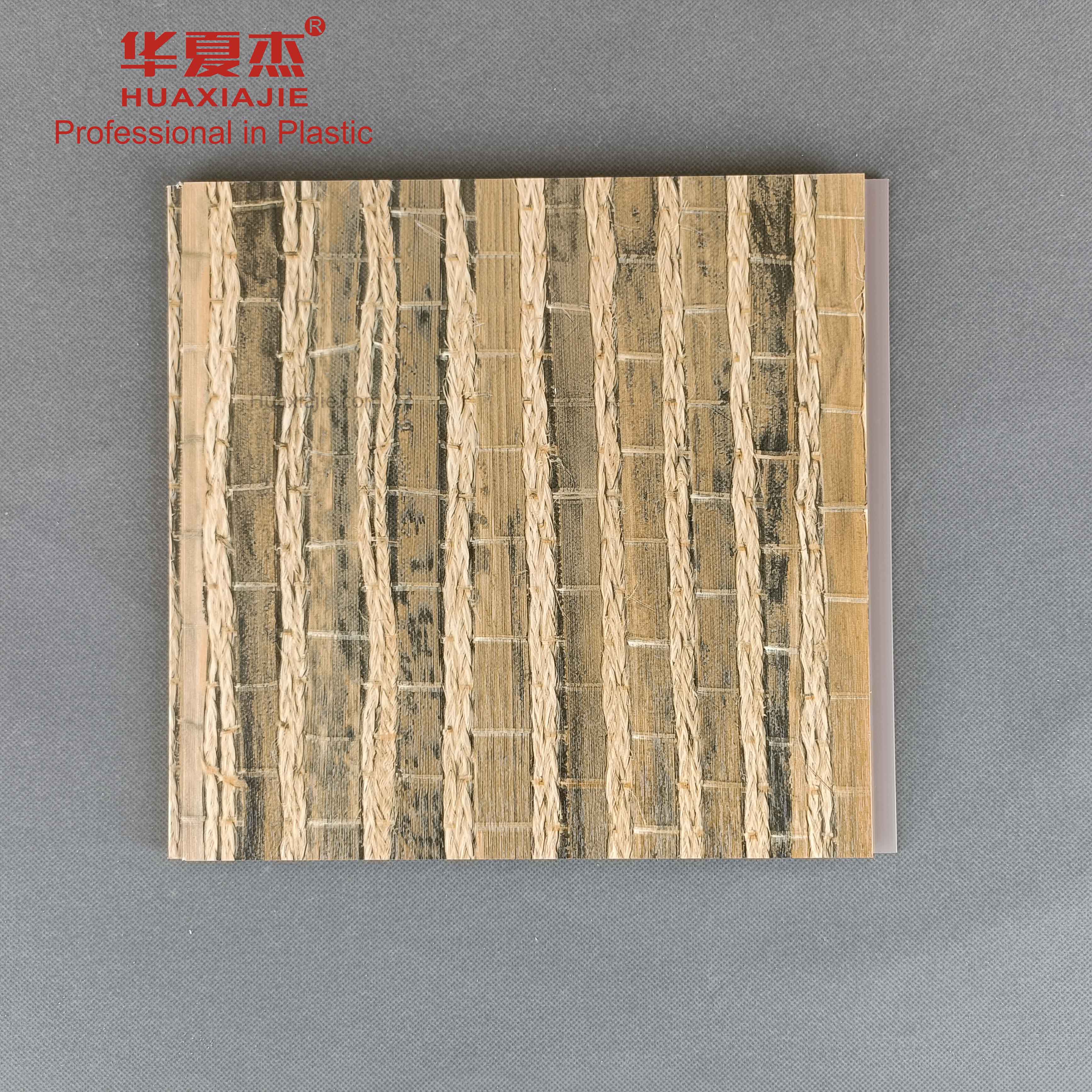

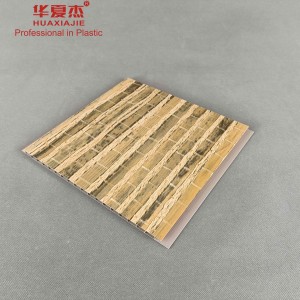

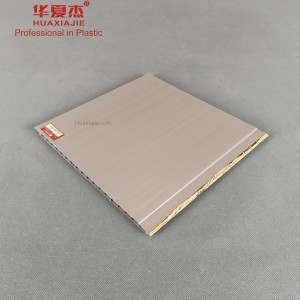

• Type: Wooden pattern or DIY

• Function: Fireproof, Heat Insulation, Moisture-Proof, Mould-Proof, Sound-Absorbing, Waterproof

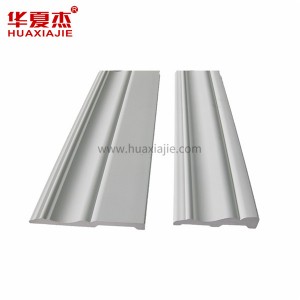

• Feature: Artistic Ceilings, Honeycomb Ceilings, Integrated Ceilings, Perforated Ceilings

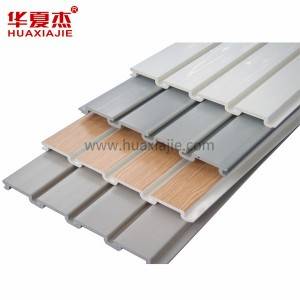

• Ceiling Tile Shape: Strip

• Material: PVC Resin, calcium carbonate

• PVC content: 50%, 60%, 73%, 77%, 87%

• Weight: 1.5-4 kg/sqm

• Surface Process: Printing, Hot stamping, Laminated

• Quality Guarantee: 25 years

• Usage: Ceiling panel and Wall panel

- Description of Recyclable Plastic Wall Covering Panels :

1. Self-fire extinguishing, non-flammable.

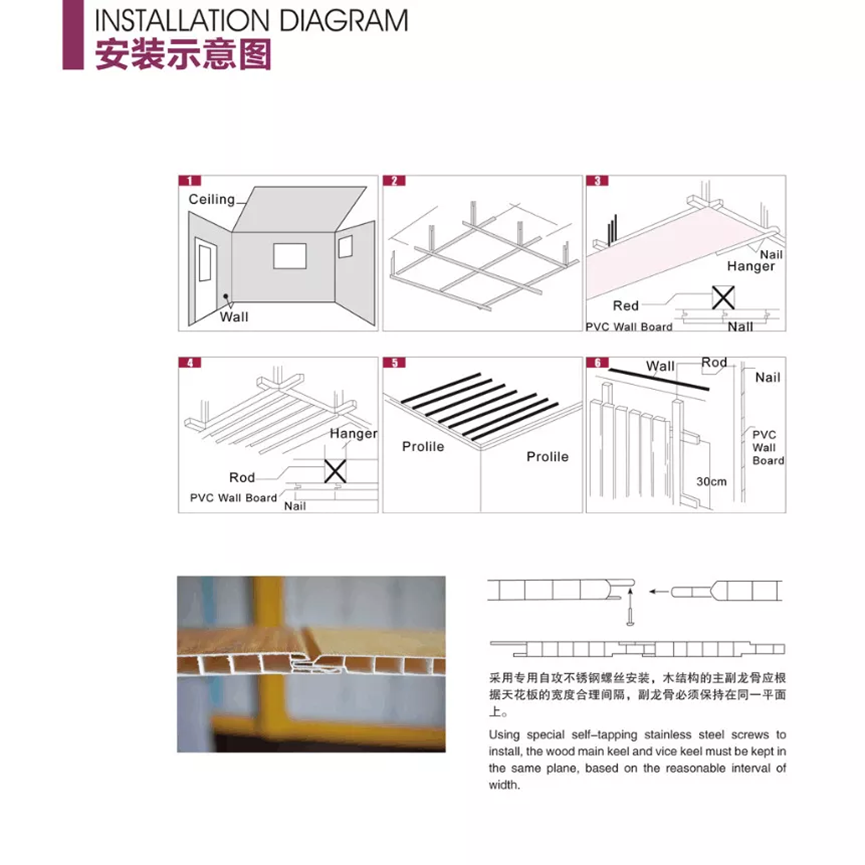

2. DIY is all right

3. It is impenetrable by insects or termites, and won’t rot or rust.

4. Resistance to weather/ special chemicals; Waterproof / Washable.

5. The excellent rigid and superior impacted surface is without any peeling.

6. Natural wood grain: showing authentic wood structure and artistic sense.

7. Easy to be cut, drilled, nailed, sawed, and riveted. .

8. Free of maintenance. No cracking, swelling and deforming; Free maintenance and keeping,easy cleaning; cost saving for the maintenance and keeping.

- Applications:

In recent years PVC has become an advantageous alternative than traditional materials for decorating and rearranging of interior spaces in the various environments such as residences, hotels, restaurants.

industrial units, individual offices, bathrooms, kitchens, laundries.

- Specifications of Recyclable Plastic Wall Covering Panels :

| Product name | Customized Size Exterior Wall Panel Recyclable Plastic Wall Covering Panels |

| Main material | PVC (50%, 60%, 73%, 77%, 87% or as your request),calcium carbonate and other chemicals |

| Usual specification | Length: customized size, such as 2.95m, 3m, 3.8m, 5.6m, 5.8m, 5.95mWidth: 5cm to 40cm or customizedThickness: 5mm to 10mm or customized |

| Surface treatment | Oil print, hot stamping foil, thermal transfer print,laminated and so on as your pattern and color |

| Surface effect | Bright/glossy, high glossy, matt, gleam, roller coating and so on |

| Production quality | Light of weight, powerful strength, high intensity, heat insulation,flame resistant, corrode resistant, age resistant, no aspiration,easy cleaning, easy installing and so on |

| Producing scale | With more than 60 PVC production lines and 100 kinds of moulds |

| Certificate | ISO9001:2000, Soncap, Intertek, SGS |

| Application | Hotels, commercial buildings, hospital, schools,home kitchen, bathroom, indoor decoration and so on |

| Sample | Free with International Express Delivery |

- Test Report

| Report No. | V03-1300143 | ||||||

| Product | PVC Wall Panel | Standard | BS EN 13501-1:2007 | ||||

| Test Items | Measure Unit | Technical Requirement | Test Results | Individual Judgment | |||

| Fire growth rate index(Figra) | W/s | C | ≤250 | 105 | Compliant | ||

| Lateral flamespread( LFS) | m | <edge of specimen | Yes | Compliant | |||

| Total heat release within600 s(THR 600s) | MJ | ≤15 | 11.5 | Compliant | |||

| Flame spread(Fs) | Surface | mm | ≤150 | 30 | Compliant | ||

| Edge | 33 | Compliant | |||||

| Smoke growth rate(SMOGRA) | m2/s2 | S2 | ≤180 | 192 | S3Compliant | ||

| Total smoke productionwithin 600 s(THR 600s) | m2 | ≤200 | 666 | ||||

| Flaming droplests/particles | —— | d0 | No flaming droplets/particlesoccur within 600s | Yes | Compliant | ||

| Ignition of the filter paper | —— | No ignition of the filter paper | Yes | Compliant | |||

| Conclusion | The combustion performance of sample issatisfied BS EN 13501-1:2007 about grade C-s3,d0. | ||||||